North Head Sewage Plant Still Pollutes, Still Smells. The Independent Pricing and Regulatory Tribunal (IPART) recently approved only one of the two additional digesters sought by Sydney Water for the North Head biosolids amplification project. As a consequence Sydney Water is currently reviewing the options that will flow from operating the plant with less equipment than they deemed necessary. The need for the second digester was supported by the New South Wales Environmental Protection Authority (EPA). The EPA advised IPART that current load limits and concentration limits for some sewage treatment plants were derived many years ago. North Head licence load and concentration limits were set many years ago. The quantity and composition of the material pumped into the ocean at North Head The current EPA licence load limits the discharge into the ocean at North Head is 35,011 tonnes for solids and 5570 tonnes for oil and grease also the licence sets concentration limits for discharging solids, oil and grease into the ocean. Licence Assessable Pollutants Load limits in kilograms BOD (Coastal Water) (Biological Oxygen demand) 35010800 Cadmium (Coastal Water) 283 Chromium (Coastal Water) 3011 Copper (Coastal Water) 37583 Lead (Coastal Water) 3568 Mercury (Coastal Water) 60 Nitrogen (total) Coastal Water 7957000 Oil and Grease (Coastal Water) 5569900 Pesticides and PCBs (Coastal Water) 370 Phosphorus (total) (Coastal Water) 1909680 Selenium (Coastal Water) 2387 Total Suspended Solids (Coastal Water) 35010800 Zinc (Coastal Water) 51066 Under the EPA licence millions of dollars are paid annually by Sydney Water to the State Government for the right to discharge these pollutants from the Plant into the marine environment. The impact of the cleaning process of the digesters Sydney Water has operated the treatment plant with three digesters since September 2007 and each of these digesters needs to be cleaned and refurbished and this process takes a digester off-line for seven months. One digester was cleaned in 2014, a second one was cleaned in 2015 and cleaning of the third is due to be completed in December 2016. Sydney Water’s digesters maintenance information indicates that a temporary increase in odours may occur during the cleaning process and recently, there have been days in succession when strong odours reached the two parking areas for viewing the harbour on the North Head Scenic Driveway. In addition, the number of biosolids truck movements increase only in the first month when a digester is cleaned. Biosolids trucks still emit biosolids and deodoriser odours when moving through the streets of Manly. Micro plastic particles entering the ocean Treated effluent from the wastewater treatment plants is a pathway for micro plastic particles to enter the ocean. This worldwide problem of plastic in the marine environment has made operators of wastewater treatment plants throughout the world seek solutions to the problem of micro plastics in effluent discharged to the marine environment. We hope that the New South Wales government has decided that the problem should be looked at for North Head treatment plant. Conclusion We have not lost sight of the fact that the solution sought by Sydney Water for the North Head treatment plant has not been announced. We await a decision that will lead to a better outcome for the community and the environment.

2 Comments

Upgrading Sydney Water’s North Head Sewage Treatment Plant - Latest Update

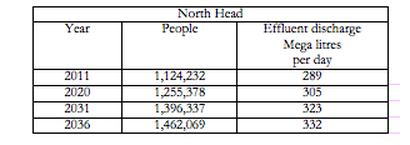

In the independent consultant’s report that was considered by IPART it was stated: “The case for two digesters appears to be based on growth projections to 2036” and the report listed the projection table below as one of three “KEY DOCUMENTS REVIEWED”. This is an interesting table but it is grossly inaccurate! Let us look at the details:

This means that IPART based its recommendation on false data. What is the current state of affairs?

Where does this leave us? At the present time Sydney Water captures about 30% of the solids that arrive at the plant - the rest is pumped into the ocean. If Sydney Water does not have the equipment to process the sewage then it would appear that one of the following options must occur:

These options are totally unacceptable. We have some questions for our Premier and local member, Mike Baird. Mr Baird can you tell us:

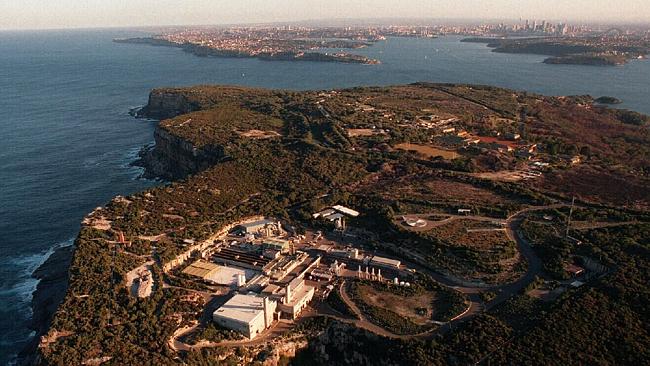

There is an interesting difference of opinion in the State government’s bureaucracy about proposals to increase Sydney Water’s plant capacity at North Head. On 22 March 2016 the NSW Independent Pricing and Regulatory Tribunal (IPART) released a draft report on Sydney Water’s proposed expenditure for the period July 2016 to June 2020. Sydney Water had sought funding for a project to amplify biosolids production at North Head Sewage Treatment Plant at a cost of $40.1M. They proposed to install two additional digesters to improve the plant’s capacity to treat sewage arising from the population growth in the catchment. IPART had engaged a consultant to consider Sydney Water’s proposals and they recommended that only one digester be approved and funding reduced by $13.3 million. They suggested that that Sydney Water had not made a strong enough case to warrant a second digester to cope with anticipated demand. IPART accepted this view. Environment Protection Authority’s (EPA) response to the draft report The EPA was concerned that the proposed reduction in capital and operating expenditure will result in a deterioration of performance of Sydney Water’s sewage reticulation networks and treatment plants. Sydney Water’s response to the draft report Sydney Water maintained that the expenditure of $40.1 million for the North Head WWTP was required to address the lack of capacity in the digesters and other limitations at the plant. The drivers cited by Sydney Water for the expenditure at North Head included the plant’s reliability, performance, inadequate digestion, high transport costs and odour complaints as well as the plant’s ability to meet the environment protection licence effluent quality and load limits. The Community response A number of members of the Manly community, including the Manly Environment Centre, also made submissions on IPART’s draft report. Given Sydney Water & Coastal Catchments pay a huge dividend to the State Government (2015 - $664m and expected to be close to a $1billion in 2016) clearly the money is there to upgrade the facility - it is a no brainer. Sydney Water want it, the community want it and the growing population of Sydney needs it. We will be watching very closely how this interplay of opinions plays out and will keep you informed of the outcome. Odour complaints relating to the North Head plant operation are an ongoing issue for Manly residents but the issue is much bigger than unpleasant smells  The Plant is surrounding by National Park overlooking the ocean. The Plant is surrounding by National Park overlooking the ocean. The North Head Plant now serves over one million people using 45 kms of pipeline from Blacktown, and ending 3ksm out to sea - a sewerage catchment of 470 square kilometres. That puts Manly at the end of the longest ocean outfall in the world. And yet North Head Wastewater Treatment Plant doesn’t have full primary treatment - only 30% of solids are captured from the inflow to the plant - the remaining 70% of solids are discharged to the ocean. Re-usable sewerage sludge, or bio-solids, are trucked out of Manly to a disposable facility way out West. All major sewage treatment plants in Australian States other than New South Wales perform secondary or tertiary treatment before discharging solids to the ocean. The Environment Protection Authority has been asked to intervene, and work with Sydney Water to achieve pollution reduction in the treatment process with recuperative thickening at the North Head plant, a move supported by Good For Manly. (Recuperative thickening is a 1967 concept in which a portion of digested sludge is thickened and returned to the digester for further digestion. It is a cost effective way to defer major capital expenditure associated with constructing additional digester capacity.) Sydney Water identified recuperative thickening as a process operation to increase digester capacity using existing assets for very little investment. The process was implemented at North Head in 2010. However latest reports show that recuperative thickening at North Head, although not run full time due to plant limitations, has had limited impact with 2015 digester performance reported as being the same as it was in 2009, before recuperative thickening was implemented at the plant. A consultant to Sydney Water stated: "… optimal digester performance is an important aspect of odour control measures." It’s interesting that recuperative thickening at Bondi Wastewater Treatment Plant achieved significant improvements: reducing biosolids production by 22%, increasing biogas production by 20% and reducing hydrogen sulphide generation from biosolids by 80%. Clearly more needs to be done at the North Head Plant! Manly Council brokered a public meeting between Sydney Water senior managers and concerned residents in November last year. The problem of unpleasant odours from the plant was the main topic, but many other issues were raised, such as decentralisation of wastewater treatment. However it became clear that there were no plans for any significant upgrades at the North Head plant. While follow up meetings with Sydney Water are planned for this year, it’s clear that unless we keep the pressure on, nothing will change. That means minimally-treated sewage will continue to be dumped into our ocean backyard and trucks transporting biosolids will continue to emit biosolids offensive odours plus deodorant in Manly on the journey to the disposal facility. Do you think this should be allowed to continue? While the admission by Sydney Water that odours at North Head are of such significance that it has allocated $4 million over 4 years to solve the problem (Sun-Herald 10/5/15) is welcomed, ongoing community concerns about actual the treatment process continue. Toxic Mercury Pollution

Sydney Water has correctly pointed out that the level of Mercury falls within the limits set by the EPA but what is not stated is that the EPA has not reduced the North Head Sewage Treatment Plant licence for Mercury discharged to coastal waters since it was established in 1992. This is a matter of great concern to the Manly community. Treatment Process In relation to upgrading North Head Sewage Treatment Plant, Project North Head Upgrade 2003 documents costed all items and it is acknowledged that major funding was needed. However the community is concerned that: 1. The 1991 planned upgrade to the ocean outfall plants did not proceed. 2. The 2002 consultation process with the Manly community undertaken by Sydney Water identified Preferred Option upgrade to full primary with 65% solids capture and secondary treatment – all within plant boundaries. However, EPA said upgrading of ocean outfall plants was not a priority and the Independent Pricing and Regulatory Tribunal believed ‘that Sydney Water has not provided sufficient justification’ for the $6M they requested. Preferred Option did no proceed. 3. As Sydney Water fails to see or acknowledge that any improvement in the treatment process is necessary that this current licence review will not lead to any improvements as well. 4. The suggestion that upgrading the North Head WWTP to secondary and tertiary treatment would necessarily result in a footprint which would reduce the size of the National Park land is unacceptable – put the plant underground, decentralise/interception with treatment along the Northern Suburbs Ocean Outfall System that flows to North Head Sewage Treatment Plant. 5. Regarding biosolids truck numbers Sydney Water has repeatedly told the Manly community the treatment at the plant dictates the number of biosolids trucks and to minimise truck movements the treatment option would be anaerobic digestion followed by heat drying. Sydney Water states that 30% of solids are removed from the influent – that means 70% of solids are discharged to the ocean which is not acceptable. This is simply not appropriate to Sydney’s image as a clean city in the 21 century that we continue to dump our sewage in the ocean. It is worth noting that in a print article about the North Head Sewage Treatment Plant Mercury pollution, the Associate Professor at the School of Civil and Environmental Engineering UNSW, Stuart Khan was quoted as saying “the real solution though would be to apply more advanced treatment processes, which are commonly employed at sewage treatment plants around the world. In the US, the EPA has banned the discharge of primary Sewage to the ocean”. It is time to start planning to implement the ‘ultimate aim’ of Section 27(1) of the Sydney Water Act 1994, which states, inter alia : ‘the corporation is to adopt as an ultimate aim the prevention of all dry weather discharges of sewage to waters, including from ocean outfalls, except to the extent that this is necessary to safeguard public health or prevent environmental degradation, or both.’ (Our thanks to Beverley Trevenen who assisted providing the facts for this article) The environment license for North Head Sewage Treatment Plant is up for review, with public submissions a part of the review process.

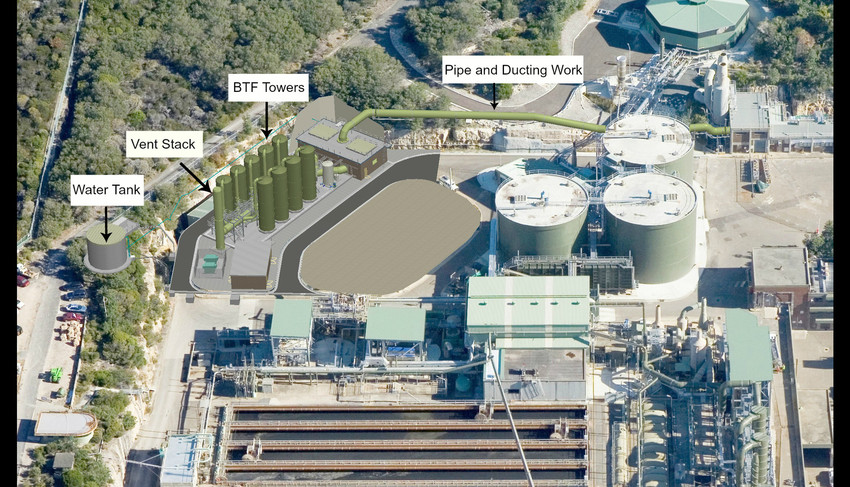

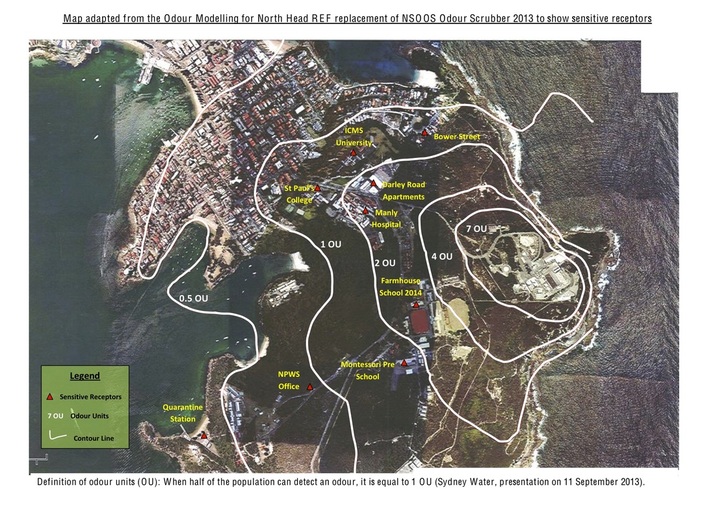

The Plant serves nearly one million customers from Blacktown, along the suburbs north of the Parramatta River to the Northern Beaches. It treats on average 345,000 tonnes of wastewater every day. Since the sewage plant began operations in 1986, the Manly community has criticised its failure to treat sewerage adequately before discharging it into the ocean. As well, offensive odours have been an ongoing problem and recently plant operator Sydney Water was named as the nation's biggest dumper of mercury - a heavy metal toxic to the marine environment. While major sewage treatment plants in every other capital city in Australia perform a two or three stage treatment process, the North Head Plant carries out one stage only before releasing sewage into the ocean. And even this one stage - screening - is not a full treatment. The screening process at North Head, which is meant to filter grease and solid material from sewage, only removes 30 % of this material, meaning that 70 % of sewage solids go straight into the ocean. And materials which are dissolved or suspended in the wastewater, nutrients such as phosphates and nitrates, and bacteria, viruses and parasites are not removed at all. This minimally-treated sewage is then pumped into the ocean 3km off-shore. In the USA and throughout the European Union this sort of pollution has been illegal for years. The bio-solids are trucked out of the area, twice a day, leaving a pong everywhere they travel. But sometimes the sewage is not even pumped out to sea. Recently a severe storm coincided with a power outage. North Head plant has no back-up power generator, so it could not pump sewage off shore. Due to the storm, there was a big inflow of storm water which exceeded the capacity of its tanks. So the plant discharged minimally-treated sewage right at the North Head cliff face. This is incredibly inappropriate anywhere, but it's outrageous at Manly which, along with the rest of the Northern Beaches area, is a major tourist attraction and one of Australia's most popular areas for swimming and surfing. The State Government has made many promises to improve the quality of effluent discharged by the North Head Plant, including a promise twenty five years ago for full three-stage (tertiary) treatment of sewage at the plant. None of these promises have been honoured. In a written submission Good For Manly has called on the licensing authority - the Environment Protection Authority - to address these problems in its assessment of the North Head Sewage Treatment Plant. Specifically, Sydney Water's license to run the plant should only be renewed if it commits to upgrading to full primary and secondary sewage treatment and to providing back-up power in the event of a power outage. As well Sydney Water must eliminate North Head's offensive odours and slash the amount of mercury discharged into our marine environment. Good For Manly Cr Candy Bingham has asked Manly Council to formally write to local MP and State Premier Mike Baird asking, as a matter of urgency, for funds for a back-up power generator for the North Head Treatment Plant. Update - Sydney Water Responded to our blog with the following comments: Mercury dumping · Sydney Water is the largest water utility in Australia servicing around 4.6 million customers across our area of operation. Our plants at North Head and Malabar are the largest in Australia, treating and safely discharging the waste of more than two million people every day, helping to protect the community and environment. · In the 2013/14 financial year Sydney Water discharged a total of 30kg of mercury from North Head and 9.2kg from Malabar. This was reported in the latest data from the National Pollutant Inventory (NPI), which details omissions from over 4,300 industry facilities. · The level of mercury discharged from North Head and Malabar in 2013/14 falls well within the licence limits of 60kg/yr at North Head and 103kg/yr at Malabar, which are set by the EPA and are implemented through the Environment Protection Licence for each plant. · In fact, the concentration of mercury discharged is at least 10 times less what is considered safe to appear in drinking water and at no stage has Sydney Water breached its Environment Protection Licence. All of our plants adhere to strict environmental requirements set by the EPA, which are monitored and reported regularly. · Sydney Water does not produce mercury however it is our responsibility to treat wastewater and trade wastewater that can include traces of mercury and other metals. · This is a responsibility we take seriously, which is why we monitor our wastewater discharges for mercury and toxicity across our area of operation. · We also undertake Ocean Sediment Monitoring to see if there is any impact on marine ecosystem health at our deep ocean outfalls. · The program has been in place for over ten years with data showing no measurable impact on marine ecosystems. More information is available about this if interested. Treatment process North Head WWTP has a three step process: screening, grit removal and sludge removal. Upgrading North head WWTP to a secondary or tertiary treatment is costly and would mean North Head WWTP has a far greater footprint (which would reduce the amount of National Park and possibly encroach on the North Head Sanctuary), uses significantly more energy and would have greater number of truck movements through Manly. Additionally, ongoing monitoring of the ocean has failed to identify significant environmental differences between locations close to and remote from the deepwater ocean outfalls, which would indicate that the end product is not impacting on the local marine environment. The screens at North Head remove upwards to 100% of material greater than 5mm in size and the primary sedimentation system removes around 30% of the organic solids from the process. James Feary Plant Manager WWTP, Sydney Water. 20/5/15 =================================================================================  New work by Sydney Water should improve air quality at the North Head Wastewater Treatment Plant. The government agency plans to replace the plant's odour scrubber - air pollution control system - which is near the end of its life. Sydney Water released a statement this month saying it will replace the existing scrubber with nine bio-trickling filters and replace or repair associated infrastructure including duct work, a water tank and ventilation stacks. Odour scrubbers function to remove particulates and/or gases from industrial exhaust streams, reducing odours and improving air quality. The news will be welcomed by Manly residents, particularly in the Little Manly Precinct, who have regularly complained of bad smells from the plant. Sydney Water had previously said that the scrubber would not be replaced until 2015. Sydney Water has prepared a Review of Environmental Factors which will be publicly available from Oct 23 to Nov 11 at Manly Council, Manly Library and Manly Environment Centre. Information related to North Head odours and Manly's troubled existence with the sewerage treatment plant is below. This Odour Map, from a recent Sydney Water presentation, shows the spread of odours from the North Head Wastewater Treatment Plant. 1OU (odour unit) means that about half the population can smell an odour. A recent report from the NSW Ombudsman reveals poor maintenance and operational practices at the North Head Wastewater Treatment Plant and the difficulty in forcing the plant's owner, Sydney Water, to deal with the problem. The report, dated August 2013, deals with complaints made by several people about strong sewage odours on North Head on February 24 2010. The odours were so bad that people reported headaches, sore eyes, dry retching and difficulty breathing. The symptoms suggested an emission of hydrogen sulphide gas, probably caused by the North Head Wastewater Treatment Plant operated by Sydney Water. The matter was referred to the ombudsman's office after it was inadequately dealt with by the Environmental Protection Authority (EPA) - formerly the Department of Environment Climate Change and Water. The ombudsman found that the original EPA investigation had raised a number of serious concerns, including "an apparent failure" by Sydney Water to properly maintain or operate the North Head plant and equipment. Record keeping at North Head, and training and supervision of staff were also found to be problematic. However in October 2010 the EPA dropped the investigation without reaching a conclusion and without taking any action against Sydney Water. The ombudsman's brief was not to investigate the original odour offence, but to consider how the EPA had dealt with it. The report makes a number of recommendations aimed at helping the EPA force Sydney Water and other government agencies to comply with their environmental responsibilities. The ombudsman did not criticise the EPA's original investigation or take action against Sydney Water.

More information is available at sydneywatertalk.com.au

Let us know what you think? Should Sydney Water do more to make sure Manly's air and ocean outfall clean.  There has been many complaints made to North Head Sewage Plant about the smells from the plant drifting across residential areas. Last year DECCW (Dept. of Environment, Climate Change and Water) decided to investigate but the decision to prosecute Sydney Water stalled because supposedly they couldn't prove that the odours came from NHSTP. Visitors to North Head, the residents in the area, members of North Head Sanctuary Foundation, who spend a lot of time at North Head, can all attest to where the odours come from so why isn't something being done?. What concerns locals is that the smell is a combination of sewage odour and chemical treatment. What damage is being done to our environment, and to the residents who live in the path of the odour drift? Last year the federal government's National Pollutant Inventory showed Sydney Water's North Head plant dumped 24 kilograms of mercury off Manly in 2009-10. Although there has been a major upgrade of the facility, the smells still continue - which makes us wonder, what are the figures now? Just what, and how much is still being dumped off Manly?? Local member, Mike Baird, has convened a meeting this week with Sydney Water, local residents and the Infrastructure and Biodiversity Regulation. Let's hope we can get some answers, and solutions. (Residents should record dates of odour complaints and report incidents directly to EPA (DECCW) ph 131555 or John Keegan, who is monitoring the issue on behalf of Little Manly Precint: [email protected]. What do you think about this issue? |

AuthorCandy Bingham, Deputy Mayor & Manly Ward Councillor on Northern Beaches Council. Background in marketing, public relations and community engagement. Author of five business books. Former Lady Mayoress of Sydney. Aka Candy Tymson. ........................................

View Videos

|

||||||||||||||||

|

Contact our team |

Site design by Manly Mac Art.

We acknowledge the Traditional Owners of the Northern Beaches and pay our respects to Elders past, present and emerging.

Authorised by Jonathan Trope, 1/90 Lauderdale Ave, Fairlight 2094

RSS Feed

RSS Feed